What are the advantages of Fabro KNX compared to standard touch panels?

Fabro KNX is designed specifically for demanding environments. Unlike standard panels, it offers IP67 protection, a solid aluminium housing, a seamless glass front and certified resistance to dust, moisture and dirt. This allows it to be used reliably even where conventional panels would quickly fail.

In which project scenarios is the use of Fabro KNX particularly worthwhile?

Typical application areas include environments with high levels of dirt or strict hygiene standards – for example food processing, agriculture, greenhouses, outdoor installations or industrial workshops. In these cases, robustness, easy cleaning and reliable operation are key for operational safety.

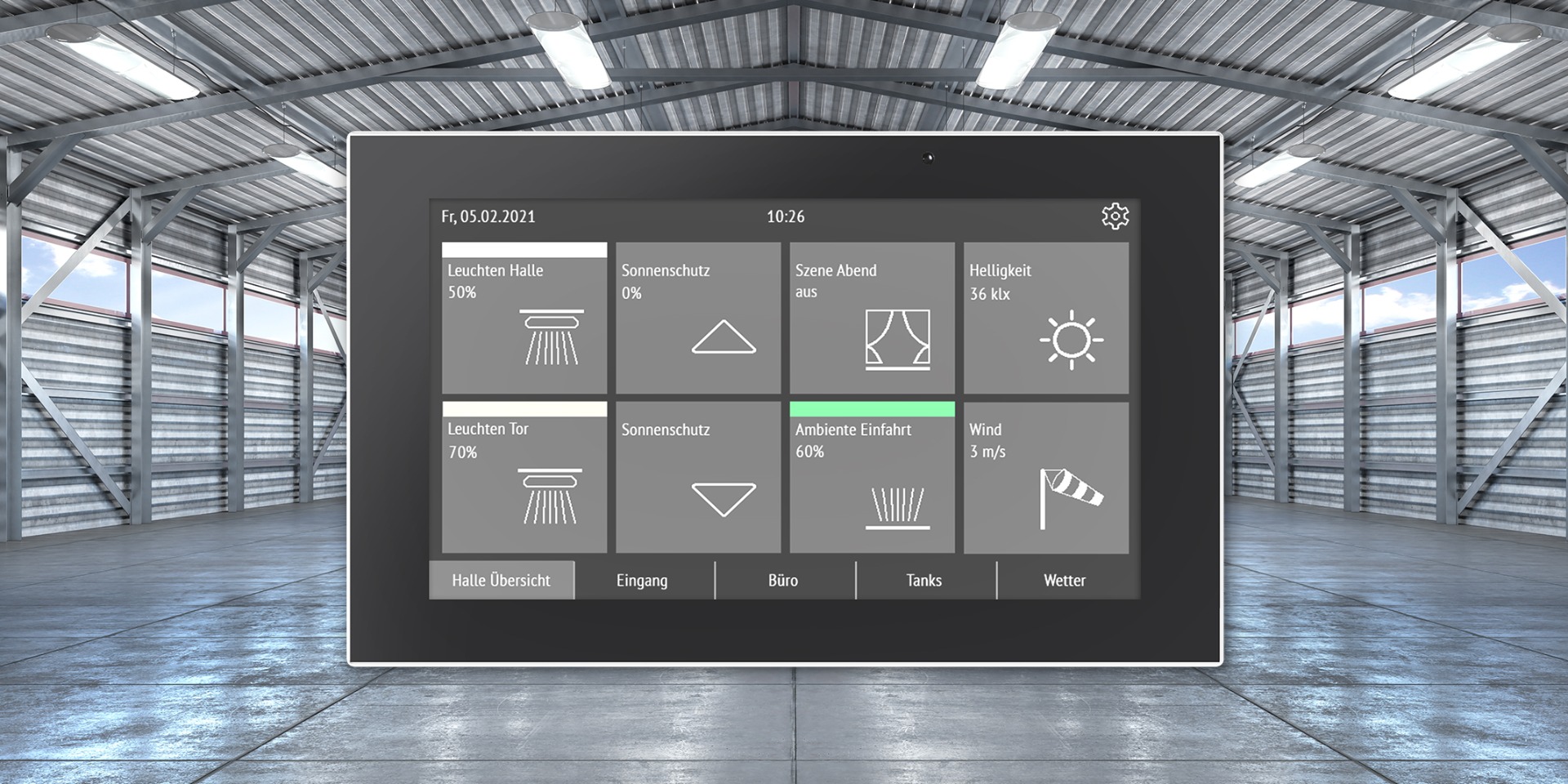

What customisation options are available for the user interface?

Integrators can tailor the user interface to the project: each page provides eight individually assignable fields, which can be combined with more than 100 symbols, texts, values and colour fields. Colours and layouts can be adapted to client requirements, making it possible to comply with corporate design specifications.

What power supply is required?

Fabro KNX requires a SELV power supply of 20–30 V DC according to EN 61558. Power consumption is max. 140 mA at 24 V DC. In addition, the device is connected to the KNX bus (TP1-256).

How many communication objects can be used in a project?

The panel provides 336 communication objects, with up to 1,024 group addresses and 1,024 assignments. This makes it suitable for larger projects and complex scenarios.

Are integrated logic and alarm functions available?

Yes. Fabro KNX features 8 AND and 8 OR logic gates with 4 inputs each, as well as 8 multifunction modules for calculations, conditional queries or data point type conversions. In addition, 8 alarm inputs are available that can trigger text messages, acoustic signals or flashing display backlighting.

How is parameterisation carried out?

Configuration is performed in S-Mode using ETS. Functions, layouts, symbols, logic modules and alarm messages can be assigned project-specifically. Thanks to the flexible interface, up to 5 display pages with 8 fields each can be individually parameterised.

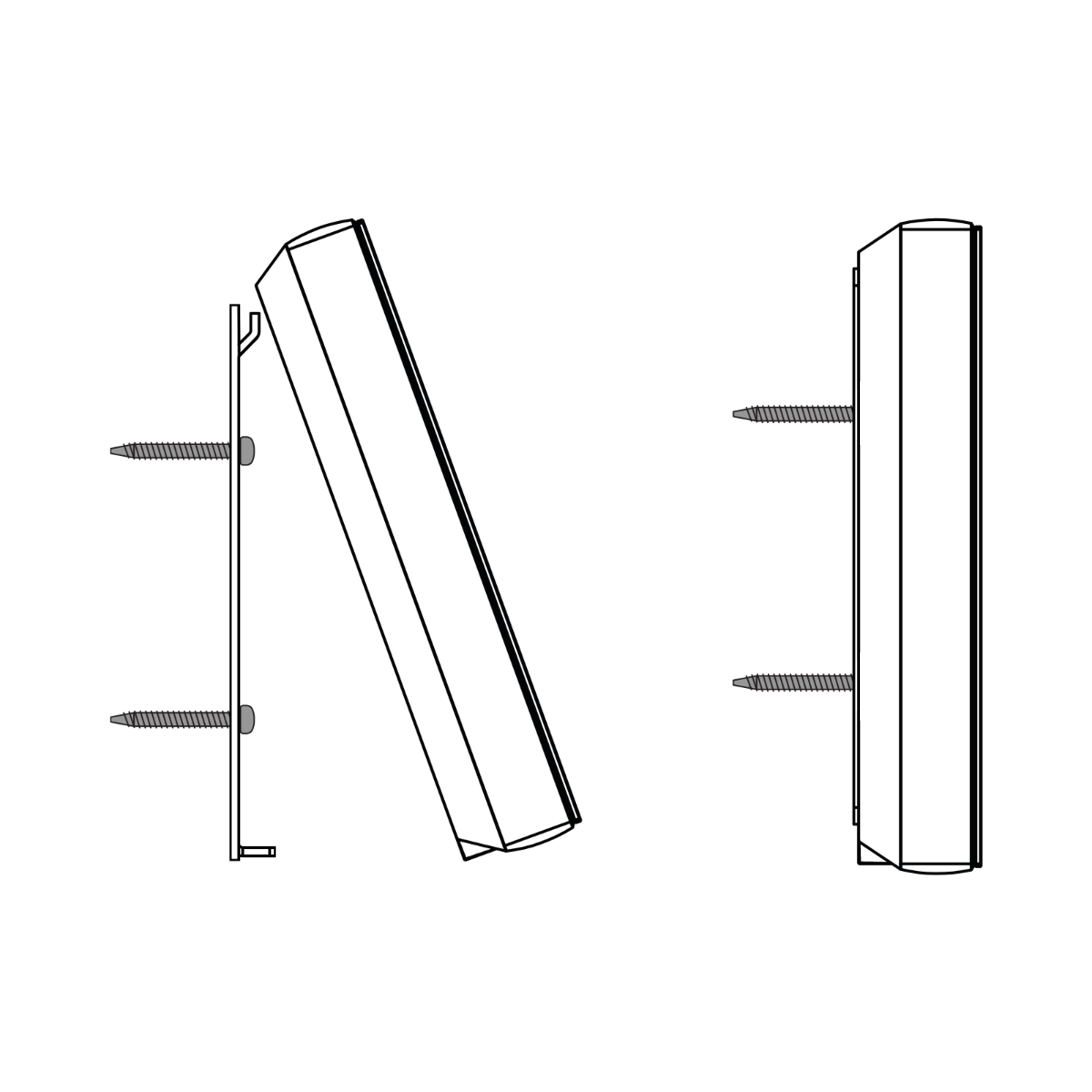

What protective measures must be observed during installation?

- Installation must be carried out exclusively by qualified professionals.

- Do not install in hazardous (Ex) areas or in corrosive atmospheres (e.g. with chlorine gas).

- Connection cables must not come into contact with 230 V mains wiring.

- The climate membrane on the rear must remain unobstructed to ensure pressure equalisation.

Are there any particular requirements for cleaning and maintenance?

Fabro KNX is maintenance-free and contains no moving parts. If necessary, it can be wiped clean with a soft, dry cloth. Aggressive cleaning agents or solvents should be avoided.

Author: Elsner Elektronik Editorial Team | Last updated: 09/2025